- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: Shandong, China (Mainland)

- Brand Name: TK

- Model Number: 6-35kv

HV Corrugated Aluminum XLPE Insulated Power Cable

High Voltage (HV) Aluminum Corrugated Cross-linked Polyethylene (XLPE) insulated Power Cable

With Rated voltage 66-220kV

high voltage corrugated XLPE power cable

Referred Latest Standard

Rated Voltage Referred Standard

66kV IEC 60840

110kV IEC 60840

220kV IEC 62067

Type: Aluminum Corrugated Sheathed Cross-linked Polyethylene(XLPE) Insulated Power Cable

Items Designation

Core type Copper or Aluminum

Insulation Cross-linked Polyethylene(XLPE)

Metal sheath layer Corrugated Aluminum

Out sheath PVC or PE

Low-smoke low halogen, anti-termite and fire retardant type aluminum corrugated sheathed cross-linked Polyethylene(XLPE) Insulated power cable can be ordered as your requirements.

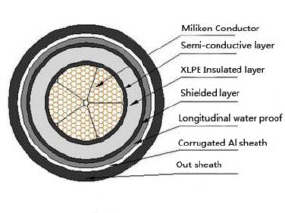

Construction

66kV to 220kV HV corrugated sheathed XLPE Insulated power cable

a. Conductor (800mm and below apply compacted conductor, above apply milliken conductor)

b. Semi-conductive shielding layer for conductor

c. Cross-linked polyethylene (XLPE) insulation layer

d. Semi-conductive shielding layer for insulation

e. Longitudinal water proof buffer layer

f. Corrugated aluminum sheath (coated with anti-corrosive bitumen )

g. PVC/PE out sheath and semi-conductive layer (coating or extruding layer)

Featured Character and Environment Condition

a. Maximum conductor working temperature is 90 ceils degree. When short circuit (time less than 5 second), the maximum temperature won’t be more than 250 ceils degree.

b. Permitted maximum lateral pressure shall be 5 KN/m

c. Maximum tensile strength: Copper conductor is 70 N/mm2, Aluminum conductor is 40N/mm2

d. The ambient temperature of laying cable shall be more than 0 ceils degree, and the minimum bent radius shall be more than 20 times of outer diameter

e. The out sheath layer: PVC or PE materials

PVC material is mainly for the requirements with average level for fire retardant and insulating cable line requirements

PE material specialized in higher requirements over insulation, humid environment for direct buried cable system. And low toxic requirement when get burnt.

Product Technology

a. Conductor

Fire retardant, anti-termite, low smoke low halogen XLPE cables

The copper conductor comes from 8mm (diameter) rod, conductivity is better than 100% IACS, oxygen content is less than 18 ppm.

As for aluminum rod, treated by rare earth, with diameter of 9.5mm, the electrical and mechanical performance have been prompted greatly.

The conductor are stranded by copper or aluminum wires. For the cross section area, 800mm2 and below apply compacted circle stranding process, which makes better roundness and high coefficient of compactness. As for the conductor area more than 800mm2, applying Milliken conductor, reduce skin effect, reducing AC resistance, which increase the capacity of power transmission.

When stranding the conductor, waterproof buffer material can be added to realize the longitudinal water proof character.

b. Insulated and shielded layer

Insulated and shielded layer adopts DOW XLPE material. Triple-layer co-extruded technology (VCV) production lines are imported from Maillefer company from Finland, and completely controlled by computer.

Fully-dry cross-linking cooling process prompt the insulated performance.

c. Semi-conductive water-proof buffer layer

High quality semi-conductive water absorption swelling belt coated on the insulated layer cores act as the buffer layer of longitudinal water-proof.

d. Corrugated aluminum sheath

Corrugated arc welding aluminum structure meets the capacity of short circuit, also light-weighted, great strength, easily to be bent, water-proof, anti-corrosion, etc. Outside of the sheath is a layer of bitumen.

e. Out sheath

PVC or PE material are extruded on the outside of the cable act as a protection layer.

Low smoke low halogen, anti-termites, double layer sheaths can be applied according to customers’ requirements.

On the outside of the protection layer, semi-conductive layer should be added, there are two options acting as the electrode when testing cable, graphite coating or extruded semi-conductive layer.

- Place of Origin: Shandong, China (Mainland)

- Brand Name: TK

- Model Number: 6-35kv